|

|||

|

|

|||

|

A bit of Background and History

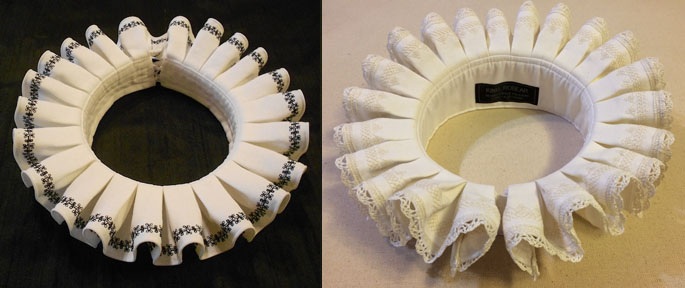

One item of renaissance attire that everyone seems to want -- but no one seems to sell at the renaissance festivals -- is the neck ruff, that elegant frill that noble and well-to-do ladies and gentlemen wear as part of their outfits. |

|||

|

|||

Some of the early neck ruffs I made entirely by hand. |

|||

|

There is a good reason for their relative scarcity: proper neck ruffs are expensive because they are tedious and take forever to make. Double-box pleating the 96-inch long strip of fabric to obtain the distinctive ribbon-candy figure-8 edge of the ruff can take some 3 hours of work just to do the pleating, not to mention the embroidery, pinning and sewing involved in completing the ruff. |

|||

|

|

|||

|

|||

|

I had been making ruffs over the years as part of whole sets of garments, but never as a stand-alone product to sell. I wanted to change that, and offer them for a reasonable price at the renaissance faires and online. |

|||

|

|

|||

|

|

|||

|

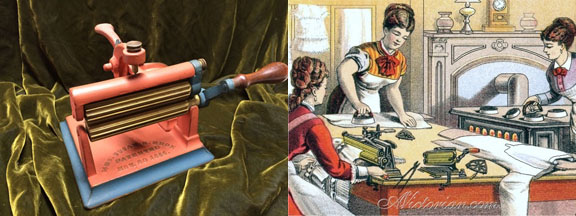

For many years I had been thinking of ways to cut the time it takes to pleat the fabric, and stop burning my fingers when doing so. A few years ago I came upon a vintage fluting iron from the 1860s. Two fluted brass rollers, heated by inserting hot cast iron rods, turned by a hand crank, effectively imprinting the fluting onto the fabric to create the crinkled flounces adorning Victorian and Civil War-era dresses. That was my “light-bulb-over-the-head” HaHa! moment. I purchased the fluting iron to study it. |

|||

|

|||

|

Then I teamed up with a dear friend from the Renaissance Faire -- who coincidentally *just* happened to be an industrial engineering genius -- and together we proceeded to develop a device that would considerably cut the pleating time, thereby turning the neck ruffs into a profitable, yet reasonably priced product. Finally, after many designs, redesigns, ale-and-wine-fueled brainstorming sessions, and several prototypes, we developed a specialized machine to reduce the time it takes to pleat the fabric from over three hours, to maybe twenty minutes, without any burned fingertips! Also -- and most importantly -- I came up with the idea of filling the ruffs' neckband with silica gel granules, which, once plumped in water, would keep the wearer feeling cool and refreshed even in the most brutal ren faire temperatures! Thus was born the "Cool Ruff"! An additional feature is that my ruffs are washable by hand, and NEVER require ironing to maintain their shape... How COOL is that! |

|||

|

|||

|

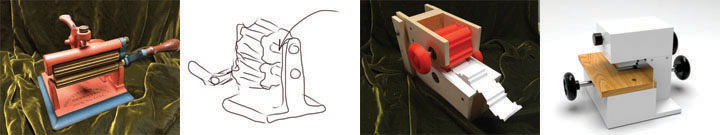

Evolution of a design, from the 1860s Fluting Iron to a first sketch, and then months later a proof-of-concept protoype made of plywood and 3-D printed plastic parts, to a sleek and very realistic-looking CAD computer rendition of the Ruff Pleater. |

|||

|

AND FINALLY... |

|||

|

|

|||

|

Here I am in my studio, turning the handle on "Pleater the Great" and creating the creases that will be gathered, pinned and stitched into an elegant Cool Ruff! |

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

King Robear You can contact me HERE . |

|||

|

|

|||

|

|